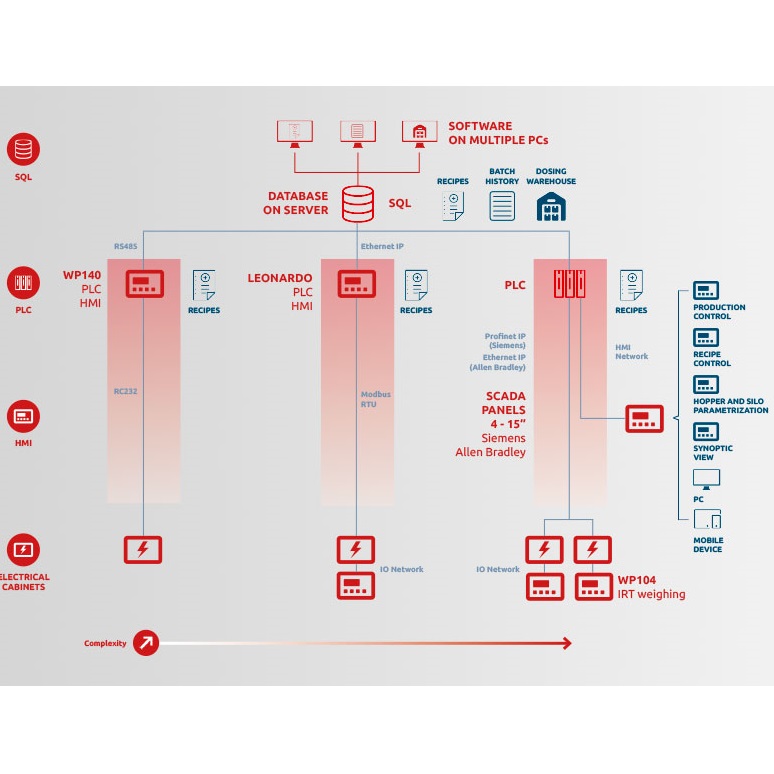

We provide a turn-key system that includes the automation. Hardware and software design is done completely in-house, and each system is the result of a decades long experience of parallel development alongside the mechanical side. With a team of 24 programmers, we provide technical and human continuity through the development of a project that can become highly specific and complex. Our solutions provide full horizontal and vertical integration, managing dialogue and data received by other partners operating in the lines, after the dosing and before the raw ingredients management. For the management of production operations, different HMIs are provided to match diverse needs: Personalized 4-15’’ touch panel on Siemers or Allen Bradley platform, for non-typical processes; native PLC Leonardo for typical processes; Weighing processor WP140 with LCD display for simple one line productions; Local control box for weight control in real time; For the management of process data, native Tracking System software provides: Full traceability, Warehouse management, Total information exchange with SQL database, Communication with ERP / MES. The automation team provides full 24/7 support.

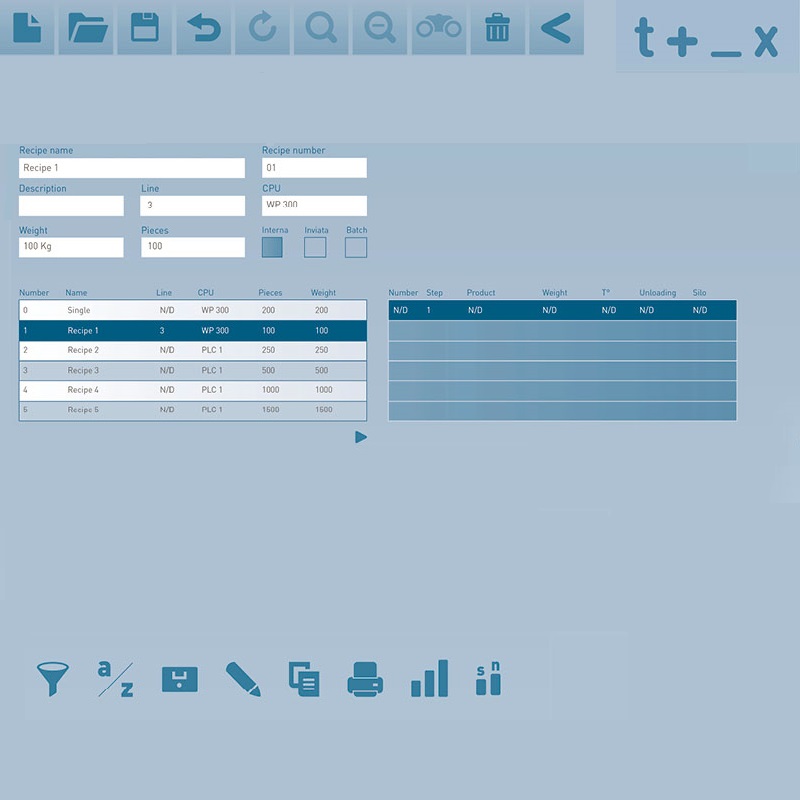

Touch panels providing production management on single or multiple lines, including: recipe creation and management, ingredient and hopper parametrization, synoptic overview with maintenance of utilities. For the management of production operations, different HMIs are provided to match diverse needs: Customized 4-15’’ touch panel on Siemers or Allen Bradley platform, for non-typical processes, native PLC Leonardo for typical processes Weighing processor WP140 with LCD display for simple one line productions Local control box for weight control in real time, The automation team provides full 24/7 support which includes: testing, optimization, start-up and training, remote support on all tools with live visualization on VPN network remote management of production and intervention on the source code virtual and personalized tutorials, live assistance with dedicated devices support from local teams who are fully trained in our devices and are part of our global network.

Native software providing process control, traceability, warehouse management, and total information exchange. For the management of process data, our native Tracking System software provides: Full traceability, Warehouse management, Total information exchange with SQL database Communication with ERP / MES. Our Tracking System provides storing and recipe data history, match report, material consumption report with dynamic visualization and digitalization of all material movements with barcode system. The automation team provides full 24/7 support which includes: testing, optimization, start-up and training, remote support on all tools with live visualization on VPN network, remote management of production and intervention on the source code, virtual and personalized tutorials, live assistance with dedicated devices, support from local teams who are fully trained in our devices and are part of our global network.